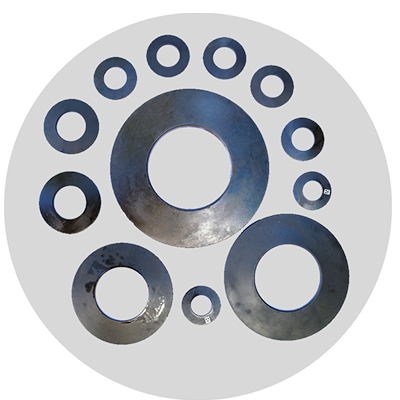

Disc Spring Washer

Wave Washer manufacturer

April 15, 2019

Disc Spring Washer manufacturer

April 22, 2019Disc Spring Washer

Uma Spring is an ISO 9001:2008 Certified Company Established in 2011. Disc Spring Washer, Belleville Washer, Conical Washer, Contact Washers, Safe Lock Washer, Heavy Duty Safety Washer, Plain Washer, Compression Spring, Sheet Metal Components, Machine Components, Wave Washer manufacturer from Surendranagar.

Disc spring Washers are conically formed angular discs which are loaded in the axial direction. They can be statically loaded as well subject to continuous dynamic loads. They can be used as a single disc or in multiple stack combination to achieve desired deflections and characteristics. Compared to a coil spring, a disc spring achieves economy in design and reduces the cost of the overall assembly by the maximum utilization of space.

Disc Springs are manufactured to DIN 2093. Materials 50CrV4 and C-80 and all parts are AUSTEMPERED. This method of heat treatment is particularly effective for springs as it gives the maximum toughness and therefore considerable durability.

Advantages of Disc Spring Washer

- Wide range of load-deflection characteristics such as straight line, progressive and regressive.

- Flexibility in stack arrangement in order to achieve the desired performance.

- Stock is minimized as the individual spring sizes can be combined universally.

- Space saving and self-damping (especially when stacked in parallel).

- No Deformation or Fatigue under normal loads. Longer fatigue life.

- Simplified inventory, an individual spring size can be used for a wide range of applications.

- High Energy Storage Capacity.

- Largely Self-damping, giving good shock absorption and energy dissipation.

- Efficient use of space and high spring force with small deflections.

- Adaptable to stacking in numerous configurations.

- Combination use as a modular spring element.

- Low maintenance cost and Long Service Life.

Features of Disc Spring Washer

- Greater security of operation service, as a failure of one Disc Spring element within a stack, does not totally lead to failure of the entire assembly.

- Spring load achieved by reciprocally alternating disc.

- Axial load achieved by the application of a guide bolt or sleeve.

- High damping capacity through friction, which can be increased by parallel stacking.

- Load, stack height, and travel can be determined and changed as needed.

We care for Quality. High-Quality products are being manufactured by adopting the latest technology.

Customer Service that is not just best but legendary. Our dedicated team monitors the specifications of Customers and satisfies their needs with our Quality Products.

All our products are competitively priced to provide the Best Value with Best Quality to our Customers.

For more details about our work please visit our website UmaSpring, or contact us at +91 (0) 2752 294 109